Search This Supplers Products:packing boxespaper bagscorrugated boxgift boxescardboard boxeslabel sticker

Packaging Boxes Making Process

time2019/07/16

- A quality box is made through a layered and complex process. Through the selection of the material of the packaging paper to control the basic quality, and secondly in the printing, laminating, bronzing, hot silver, uv and bumps and other processes continue to develop innovative new technologies to show customers more perfect packaging art.

What is the production process of the box?Peer partners know that the production of packaging boxes is a complicated process, different lines generally think that today you are called to make production, you can get it right away. In fact, every industry has its own workflow, and a qualified package is made through a number of processes.so, what is the specific process of packaging and printing?Let’s take a brief introduction to qingdao wenyang packagin.

The main communication with customers is:Whether you need design,what kind of needs are there for materials,quantity required.how much, then give the customer a quote, customer satisfaction will proceed to the next step.

In the gift box of the general packaging box, there is colored paper or special paper on the outside of the gray board paper.colored paper is made of double copper and matte copper paper.

Some are used 200g,250g,300g,350g wait,compare these heavy papers commonly used.in addition to this,there are other types of paper o choose from,such as:Ivory cardboard;white boardof gray bottom;copperplate paper;special type paper;coated paper;gold or silver foil and complex paper.

The printing is divided into spot color printing(pms) and four-colorpringting(cmyk).spot color printing refers to the printing process of copying the original color with other color inks other than the four colors of yellow, magenta, cyan and black ink.spot color printing is often used in packaging printing

process printing large area background.four-color printing is through three subtractive primary colors (yellow, magenta, and cyan)and black printed color pictures.

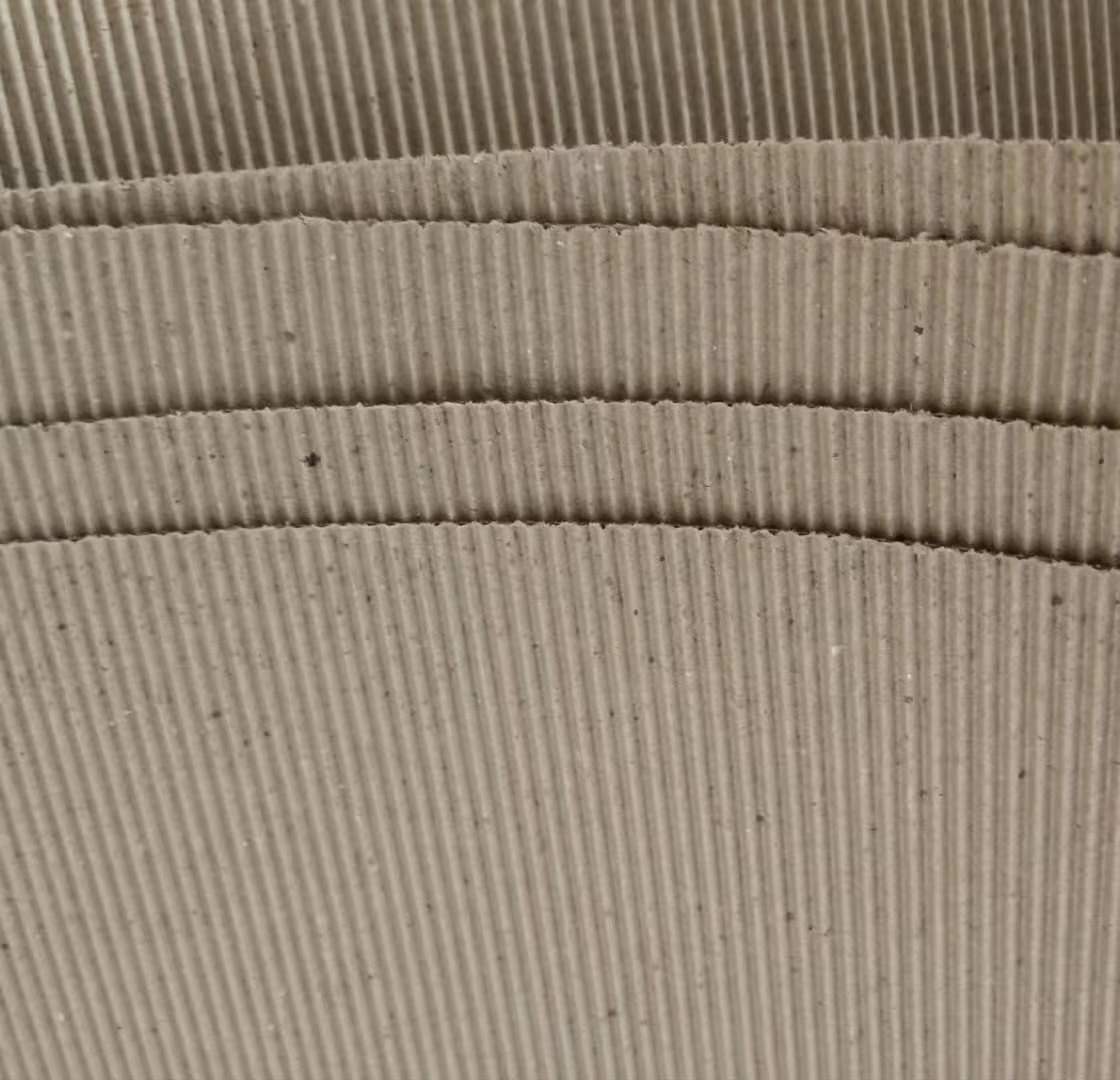

Corrugated by type: A, c, b, e and their combinations, such as: Abcorruagted, bccorruagted, bbccorruagted, etc. Corrugated paper is a board made of corrugated paper made of corrugated paper and corrugated paper formed by corrugated sticks. It is generally divided into two types: Single corrugated cardboard and double corrugated cardboard. According to the size of corrugated: A, b, c , e, f five types.corrugated paper is a board made of corrugated paper made of corrugated paper and corrugated paper processed by corrugated sticks. It is generally divided into two types: Single corrugated cardboard and double corrugated cardboard.

Die-cutting refers to a cutting process for the post-processing of printed materials. The die-cutting process can make printed or other paper products into a die-cutting die according to the pre-designed graphics, so that the shape of the printed matter is no longer limited. Straight at right angles. Die-cutting is to add the blade line to the original design when designing. After the paper is passed, the special die-cutting machine and the corresponding blade are used to press out the shape of the paper box.

According to the sample or design style,the box should be glued with the glue.it’s completed with a packing box such as a reins.

Finally, it is packaged and delivered. The above are basic processes. Let’s talk about the downstream process.

The latter process has film, hot stamping, hot silver, uv, bump:

Laminating:A transparent plastic film coated on a paper product is a film. The film is divided into "Light film" And "Dumb film". The surface effect of the film is crystal clear, colorful, and does not change color for a long time. With a soft hand and colorful surface color, it is a safe and environmentally-friendly building material that can choose colors according to the changing color perception of the times. The matte film distinguishes the color from the surface to a matte surface, matte matte matte finish.

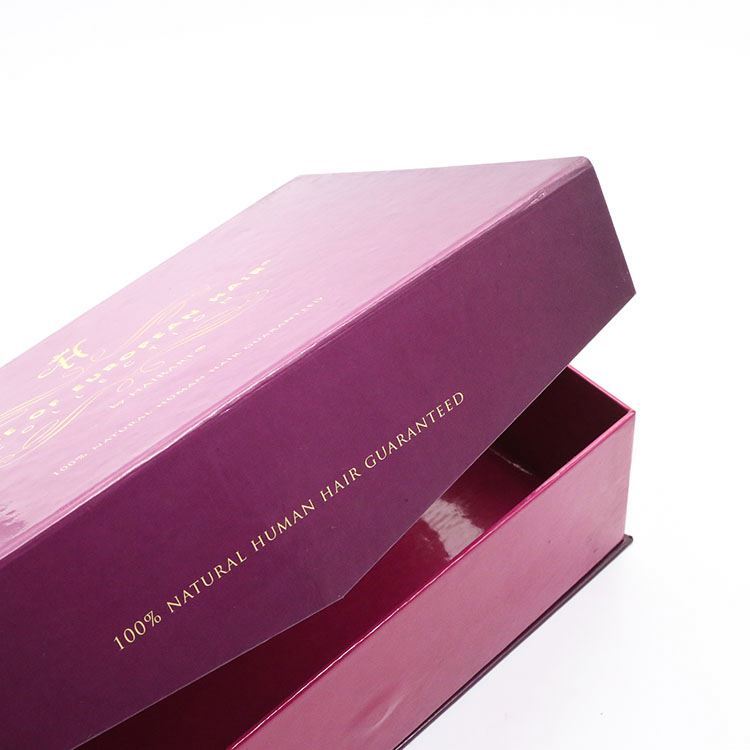

Hot stamping: Hot stamping is to heat the metal plate, apply foil, and emboss the golden text on the printed matter.

Hot silver: The principle of the process is basically the same as that of hot stamping, except that the materials used in the two havethe difference is different in appearance: One has a golden luster and one has a silver luster.

UV: Uv refers to uv glazing, that is, uv varnishing (ultraviolet), which is an ultraviolet photo-irradiation that initiates an instantaneous photochemical reaction of uv coating oil to form a bright chemical coating of a network chemical structure on the surface of the printed matter

Pressing and embossing: It is an embossing method without ink. The box is placed in a set of intaglio and letterpress corresponding to the graphic. Under a certain pressure, the two templates are pressed to make the package appear embossed and the process of the pattern.

The above is some related introductions about the packaging process of packaging production, please click Wenyang Packaging! Serviced by an excellent team!